Expanders

Gallery of images

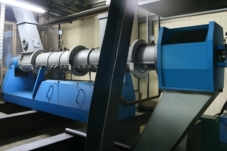

In the production of vegetable oil on an industrial scale, a combination of mechanical pressing technology followed by solvent oil extraction is used. The connecting links of these two technologies of oil production are expanders, which have been produced by “TAN” company in Ukraine for many years.

The expander is a horizontal device with a rotating screw inside, and is designed for wet-heat treatment of material (soybean petal, sunflower or rapeseed meal), obtained after mechanical pressing of oil on screw presses. The expander body is equipped with a steam jacket with nozzles for supplying steam under pressure. The complete set of all expanders of our production, in addition to the device itself, includes:

– electric motor of European production;

– oil station;

– feeder;

– granulating device;

– control and electrical panel;

– frequency converter.

After the expander, the cake takes the form of granules with all the features necessary for high-quality and effective extraction:

- porosity – provides better percolation of miscella during extraction;

- smooth structure – provides easier filling of the extractor with reduction of the amount of fine fraction;

- high permeability of expanded meal – increases the contact of the solvent with the oil-containing material, which reduces steam consumption.

So, the cake is fed into the extractor fully prepared for high-quality and effective oil extraction.

Thus, the following advantages can be received from the installation of an expander produced by the company “TAN”:

- increase in the concentration of miscella;

- extraction capacity increase (avg. for 20-30%);

- expanded meal is more porous;

- increase of extraction speed;

- reduction of steam consumption;

- reduction of solvent consumption.

The company “TAN” manufactures expanders of two standard sizes: a working chamber with diameter of 200 mm and 250 mm. They also differ in capacity. Below are the main technical characteristics of expanders produced by the company “TAN”:

Technical parameter | Brand of expander | ||

E-200 | E-250 | ||

Capacity, tpd | Sunflower meal | 100 | 200 |

Rapeseed meal | 150 | 300 | |

Soybean flakes | 300 | 600 | |

Diameter of working chamber, mm | 200 | 250 | |

Number of steam jackets, pcs | 2 | 2 | |

Working pressure in the jackets, MPa | 0,8 | 0,8 | |

Installed power of electric motor, kW | 75 | 110 | |

Installed power of feeder motor, kW | 1,5 | 1,5 | |

Installed power of hydraulic unit motor, kW | 3,0 | 3,0 | |

Dimensions, mm – length – height

– width |

6500 1700 (2200 with feeder) 2300 |

6700 1840 (2400 with feeder) 2850 | |

Weight, kg, not more | 4500 | 4700 | |

To find out the price of expanders or other equipment for the production and processing of vegetable oils use the feedback form on our website, or contact us at the indicated phone numbers. Our managers will gladly advise you on any technical issues, as well as how to buy our equipment in Ukraine or abroad.

Where is it used

Frequently Asked Questions about Expanders

What is expander for the meal?

What are the advantages of using the expanders?

- increase in the concentration of miscella;

- extraction capacity increase (avg. for 20-30%);

- expanded meal is more porous;

- increase of extraction speed;

- reduction of steam consumption;

- reduction of solvent consumption.