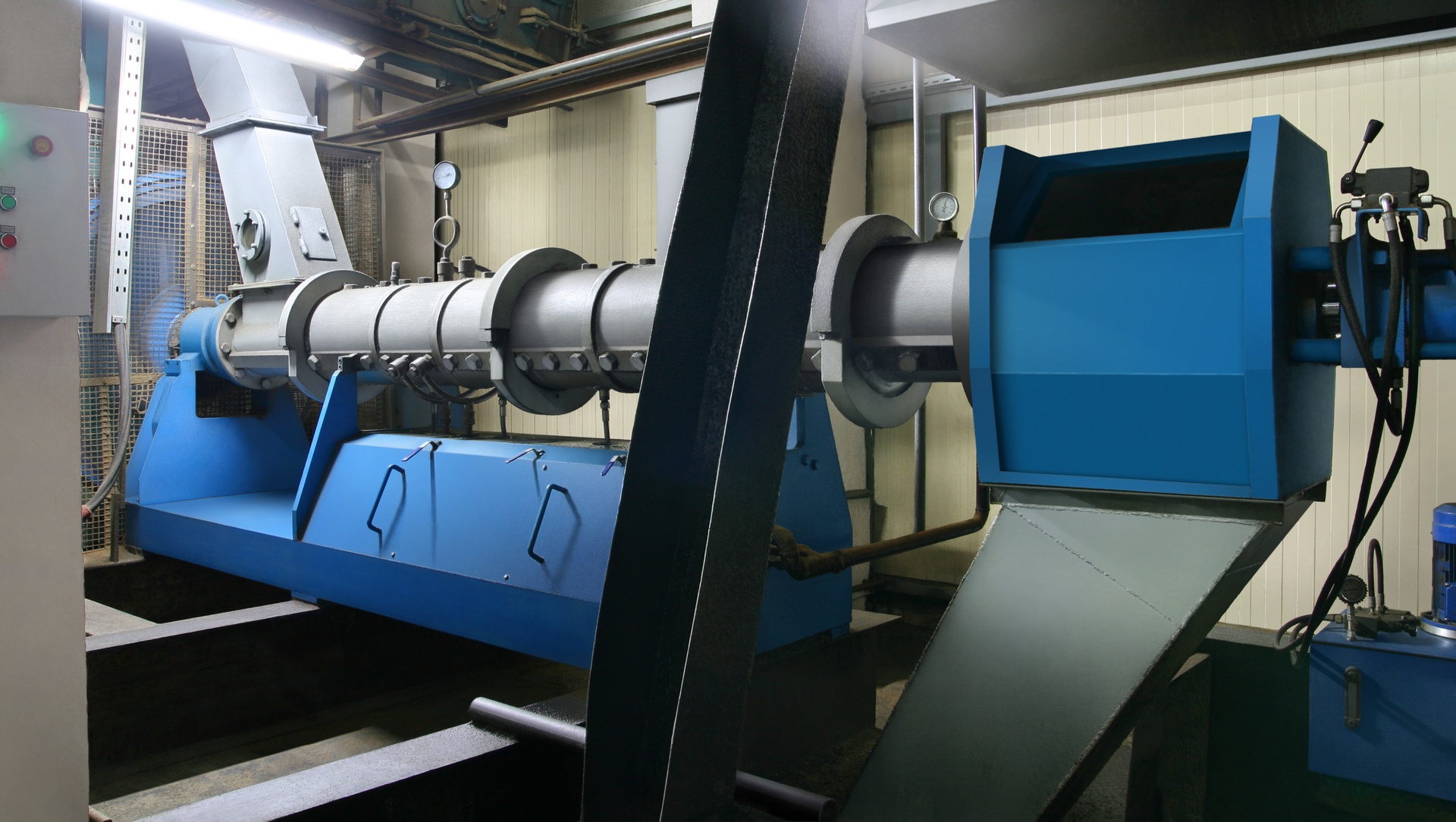

Capacity equipment for oil factory

Image gallery

Capacity equipment — industrial installations designed for storage, cooling, heating and performing other technological operations during the production and processing of edible oil. It is used in the lines of refining, deodorization, neutralization and hydration, phosphatides drying lines, and oil purification lines. In Ukraine, such technological equipment is produced by the company “TAN”. To buy tanks or find out their preliminary price, call the numbers in the header of the site or send a request by e-mail.

Categories of the capacity equipment

The company “TAN” has been working in Ukraine for over 25 years. During this time, we have highly increased our production capacities, which allows us to manufacture high-quality capacity equipment. The company accepts orders for the production of tanks and vessels made of stainless or carbon steel, including large-sized ones, up to 4.5 meters in diameter.

The “TAN” catalog presents an assortment of standard tanks with the capacity from 100 l to 65 cubic meters, which can be conventionally divided into the following categories:

- tanks with inner coils, which are designed for maximum heat exchange between two environments;

- double-walled tanks, the walls of which are made of a double steel shell;

- tanks s with a steam jacket for heating raw materials;

- tanks with mixing devices, which are equipped with gear-motors of European production;

- tanks that are designed to work under vacuum conditions;

- vessels for long-term storage of oil or other liquids.

The company “TAN” has at its own design-engineering department and a material and technical base that allows designing, manufacturing and installing tanks and vessels, screw oil presses and other devices, taking into account the wishes and requirements of the customer and the specifics of his factory.

Description of capacity equipment

Tank shells are made of carbon or stainless steel sheet metal, depending on the purpose and application. Their complete set includes hinged covers, hatches and supports, as well as fittings, flanges and nozzles for connecting additional equipment, emptying the container, supplying coolant or refrigerant.

The following parameters are taken into account before ordering the capacity equipment:

- application (collectors, accumulators, conditioning tanks, separators, etc.);

- materials (stainless or carbon steel);

- wall thickness and presence of a steam jacket (heated or unheated);

- control of electrical equipment and valves (manual, automatic, semi-automatic);

- working pressure (atmospheric, vacuum).

Depending on the axial position, the capacity equipment can be vertical or horizontal. In the first case, it is a cylindrical vessel with a flat, conical or cylindrical bottom, mounted on legs or with a supports for installation on the floor or ceilings. Horizontal tanks are made in the form of a cylindrical or rectangular vessel. They are installed on legs or a frame.

Characteristics and operating conditions of the equipment

In the production of capacity equipment, stainless steel or carbon steel is used. Component parts are connected using semi-automatic, automatic or arc welding. Due to such design the equipment can be effectively used for operation under high pressure conditions.

Advantages of tanks and vessels produced by the company “TAN”:

- resistance to aggressive external and internal environment;

- high strength;

- long service life;

- unpretentiousness in maintenance and disinfection.

Capacity equipment is only a part of production lines for extraction and processing of vegetable oil. They also include a large amount of other equipment that performs its technological operations as part of complex lines. The company “TAN” will help you to design a complex line from idea to result, or to buy separate pieces of equipment, such as cookers, extractors, expanders, etc. To check the manufacturer’s catalog or find out the prices, call the numbers in the header of the site or use the feedback form.