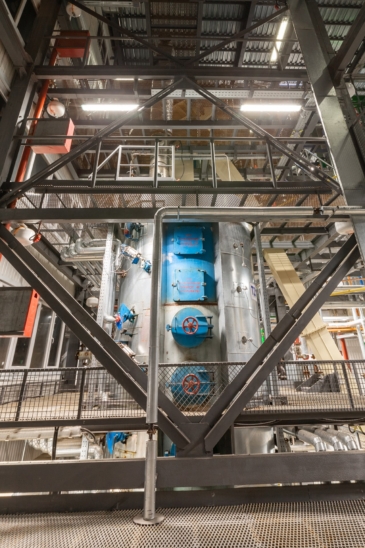

Toaster (Desolventizer)

Desolventizer, or toaster, is used for wet-heat treatment of solvent-containing meal (defatted raw material residue) of oilseeds after the process of oil extraction with a solvent. Thus, solvent residues are removed.Equipment Description

Desolventizer, or toaster, is used for wet-heat treatment of solvent-containing meal (defatted raw material residue) of oilseeds after the process of oil extraction with a solvent. Thus, solvent residues are removed.

Operating principle

Toaster is a vertical column consisting of several trays that are heated by steam. The number of trays and their diameter depends on the capacity of the extraction line on which the toaster is installed.

In the upper part of the toaster there is a cap with nozzles above the upper tray. It is used to supply meal, as well as to remove solvent vapors. Under the bottoms of the trays there are collectors with nozzles that supply direct steam through the bottom grate, which improves the process of distillation of the solvent and conditioning of the meal. Each trays is also equipped with paddle mixers, which are used to move and mix raw materials. They are rotated with a common shaft.

The toaster is also equipped with control valves – they maintain the required level of meal in the trays during the continuous operation of the toaster. Valves can change the level of meal in each individual tray, without stopping the operation of all equipment.

At the customer’s request, the product temperature at the outlet can be adjusted automatically or manually.

Technical parameters of toasters of production of TAN LLC

|

Technical parameter |

ТД-1 |

ТД-2 |

Т-2200-10 |

|

Capacity based on sunflower meal, tpd |

380 |

100-110 |

200-210 |

|

Number of sections, pcs |

5 (2 trays in each section) |

3 (2 trays in each section) |

5 (2 trays in each section) |

|

Inner diameter of the section, mm |

3200 |

2000 |

2200 |

|

Height of the meal layer in the tray, mm, not more |

370 |

370 |

370 |

|

Volume of the jacket of the tray bottom, m3 |

0,29 |

0,06 |

0,08 |

|

Volume of the jacket of the section walls, m3 |

0,06 |

– |

0,44 |

|

Type of heat transfer agent in the jackets of the trays |

Overheated steam |

||

|

Estimated technological consumption of steam, kg/hour, not more |

4500 |

1200 |

2500 |

|

Rotation frequency of the mixer shaft, rpm |

16±3 |

27±3 |

25±3 |

|

Installed power of the electric motor of the mixer drive, kWт, not more |

90 |

30 |

55 |

|

Net weight, kg |

47000 |

15000 |

26000 |