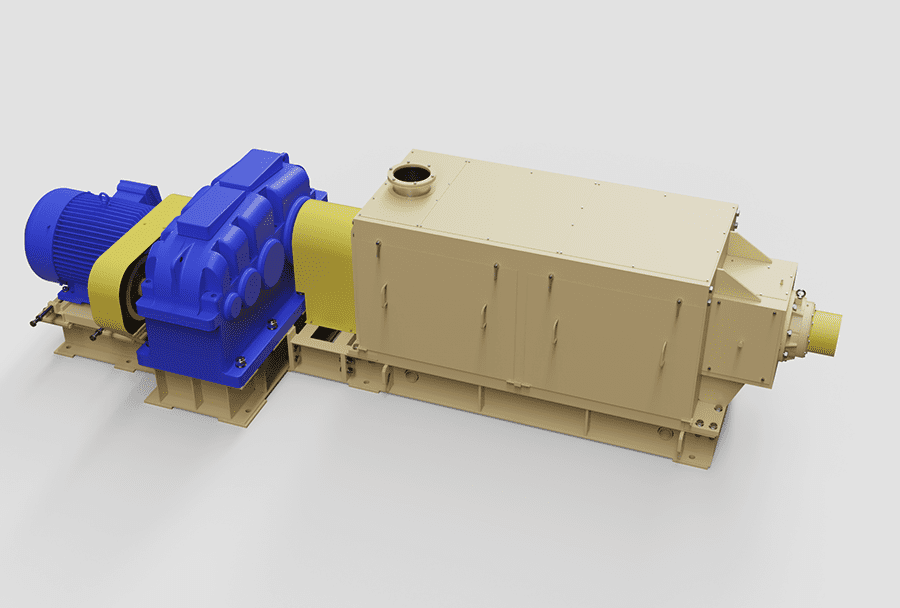

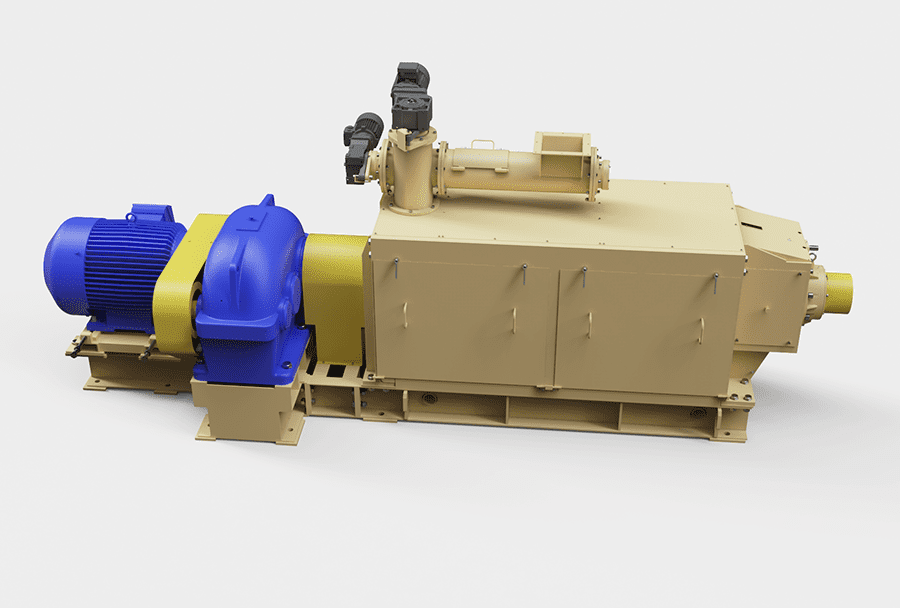

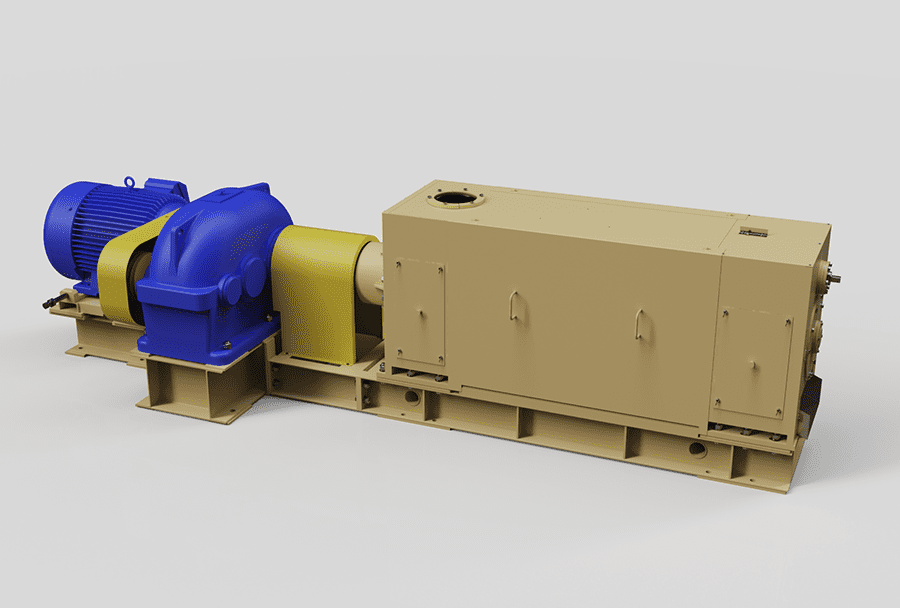

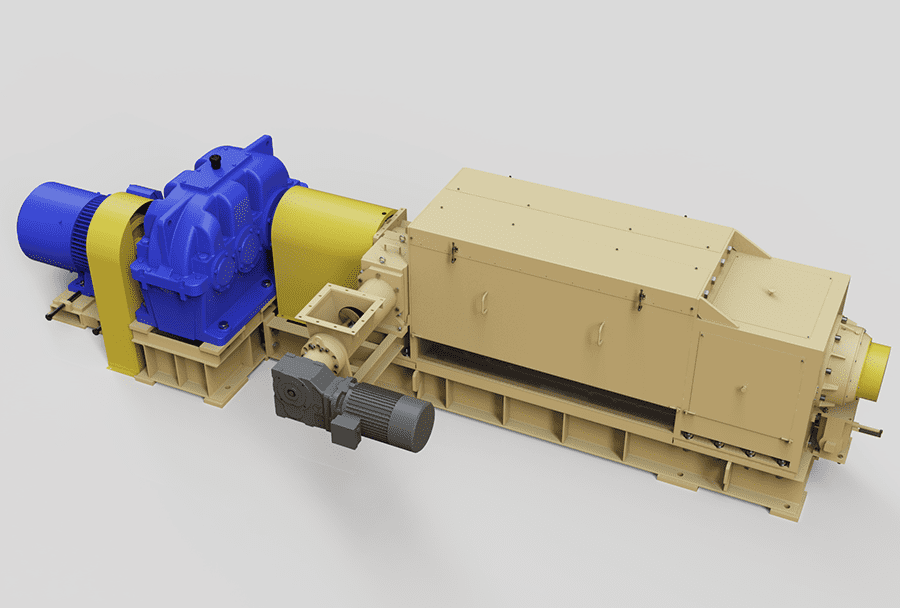

Screw oil press

Image gallery

Description of possession

Screw oil presses are designed for continuous mechanical extraction of vegetable oil from crushed oilseeds (sunflower, rapeseed, cake, soybeans, etc.).

The main product obtained after pressing is vegetable oil, the secondary product is a oilcake in the form of a shell with a residual oil content.

The principle of action

Screw press is a prefabricated welding frame with closed lining. In the frame there are bearing supports of the screw shaft and units for mounting of the loading case, the pressing cage, the bath for oil drainage, the channel for the oilcake exit. The transmission of torque from the motor is carried out by means of a V-belt transmission, and from the gearbox to the screw shaft – by a special cam-disc coupling. During the operation of oil press, the prepared material is fed by a screw shaft into the pressing cage through the feeder and the loading case, where the oil is extracted. The pressed oil flows through the slots of the pressing slats into the bath, from which it is fed for further processing. The pressed material (oilcake) comes out through the annular gap between the sleeve and the cone of the screw shaft.

Oil presses operate in a continuous mode of full mechanical load, so it is very important that all parts of the press that are in contact with raw materials (screws, pressing cages and slats, etc.) are durable. To achieve maximum wear resistance, our company carries out heat treatment of all these parts, which significantly increases their service life and reduces customer costs for the purchase of spare parts.

Each press is completed with gearboxes of the European production, frequency converters for regulation of rotation frequency of the electric motor according to requirements of individual production.

Our company produces oil presses in two variants:

– for preliminary pressing (forpress);

– for final oil pressing (expeller).

Main technical parameters of oil presses produced by TAN

| Technical parameter | Brand of screw oil press | |||

| 2ПШ-25 | ПШ-70 | ПШ-90 | ПШ-300 | |

| Usage | Final pressing (expeller) | Preliminary pressing (forpress) | Preliminary pressing (forpress) | Preliminary pressing (forpress) |

| Capacity, tpd (sunflower seeds) | 20-25 | 50-70 | 60-90 | 250-300 |

| Residual oil content in the meal, % | 8-10 | 18-22 | 17-20 | 18-22 |

| Installed power of the electric motor, kW | 45 | 45* | 45 ** | 132*** |

| Dimensions, mm – length – height – width | 4850 1300 1690 | 4500 1200 1400 | 4700 1300 (1920 with the feeder) 1300 | 6100 1450 1440 (2200 with the feeder) |

| Weight, kg, not more | 7000 | 4800 | 7500 | 9500 |

The layout of the drive system, feeders and overall dimensions may differ from those shown in the table.

* installation of forced feeder (power of the drive 3 kW) and dosing feeder (power of the drive 1.5 kW) is possible

** supplied with forced feeder (power of the drive 3kW) and dosing feeder (power of the drive 1.5kW)

*** supplied with a feeder (power of the drive 11 kW)