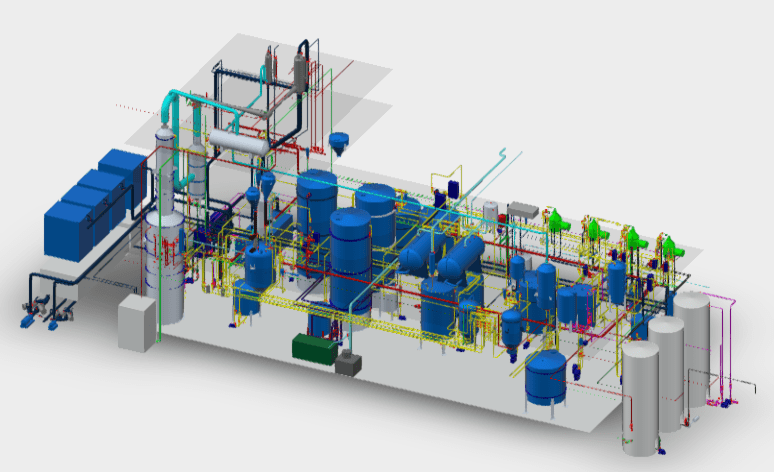

Refining-deodorizing line of vegetable oil

Our company produces technological lines for oil refining and deodorizing. The set, composition and power of the equipment varies depending on the technical task of the client. Complex refining-deodorizing lines are used to remove odorants, free fatty acids, phosphorus-containing substances, peroxide compounds, as well as wax-like and coloring substances from vegetable oils after oil extraction.

Description of technological line

Refining-deodorizing lines are designed for comprehensive deep processing of vegetable oils, resulting in a product completely devoid of color, taste and smell.

Lines for the refining and deodorizing of vegetable oils are produced by our company in two versions:

- of continuous operation;

- of periodic (batch) operation.

The capacity of our refining-deodorizing lines ranges from 30 to 500 t/day. Degumming and neutralization lines can also be purchased separately from us. You can find out the technical details of the equipment and prices of the equipment by leaving a request in the feedback form or by calling the numbers indicated in the header of the website.

A mandatory condition for putting the line into operation is an uninterrupted connection to the water supply and electrical network

The principle of operation of vegetable oil refining-deodorizing line

Refining-deodorizing technological lines are divided into separate sections. Each section of the process requires separate specialized equipment. Complex refining-deodorizing lines consist of four sections/lines:

- Degumming and neutralization line, the main purpose of which is to clean the sunflower oil from phosphorus-containing substances and other hydrophilic impurities, neutralize free fatty acids, as well as wash out soap from the oil and formation of soap stock. The large amount of technological equipment is used in the line, in particular, capacitive equipment

- Bleaching (adsorption) line, which is designed to remove coloring substances, as well as a certain amount of peroxide compounds and phosphorus-containing substances. The removal of chlorophyll pigments is very important because they are not removed in any other refining step like carotenoid compounds in deodorizing process. The main equipment of the line: vacuum bleaching devices, filters of the brand ВНП and ГНП. The filters are also used in the process of winterization.

- Winterization line, the technological purpose of which is to remove waxes and wax-like substances contained in oil.

- Deodorizing line, which is used to remove odorants from the oil – substances that determine the characteristic taste and smell of the oil. Deodorizing process is carried out by exposing the oil to superheated steam. Before sending to the deodorizer, the oil must be thoroughly refined, without traces of soap and bleaching clay. Basic equipment: deodorizer with hot steam supply, tanks and vessels, and police filters.

The deodorizing process is the fourth stage of vegetable oil refining, which begins after bleaching and winterization. Deodorization greatly affects the quality of refined oil and is considered as the heart of the entire edible oil refining method.

“TAN” LLC offers complex refining-deodorizing lines. The price depends on the configuration of the line, technological characteristics of the equipment and capacity. The configuration and performance of the lines, the terms of delivery are pre-agreed with our specialists, taking into account the requirements of the customer. You can find out more about each individual plot on the corresponding page of our website. We also manufacture fat interesterification lines to purify oil from transisomers.