Cookers for oil factory

In the production of edible oils, the technology of mechanical pressing is widely used. But before that, the raw materials are subjected to a preliminary wet-and-heat treatment, with the help of which the necessary temperature and humidity of material are achieved. For this purposes the cookers are installed in the oil workshops. In Ukraine, they are manufactured by the company “TAN”. To find out the price of the cooker, extractor or other turnkey equipment, contact the numbers in the header of the site or use the feedback form.

Types of cookers for oil workshops

“TAN” company manufactures cookers for the production of vegetable oil of various sizes and configurations. First of all, they can differ by:

- capacity;

- heat exchange area;

- installed power of the drive.

The company has at its disposal a design and engineering departments who will design a production line taking into account the scale of the enterprise, the requirements and wishes of the client.

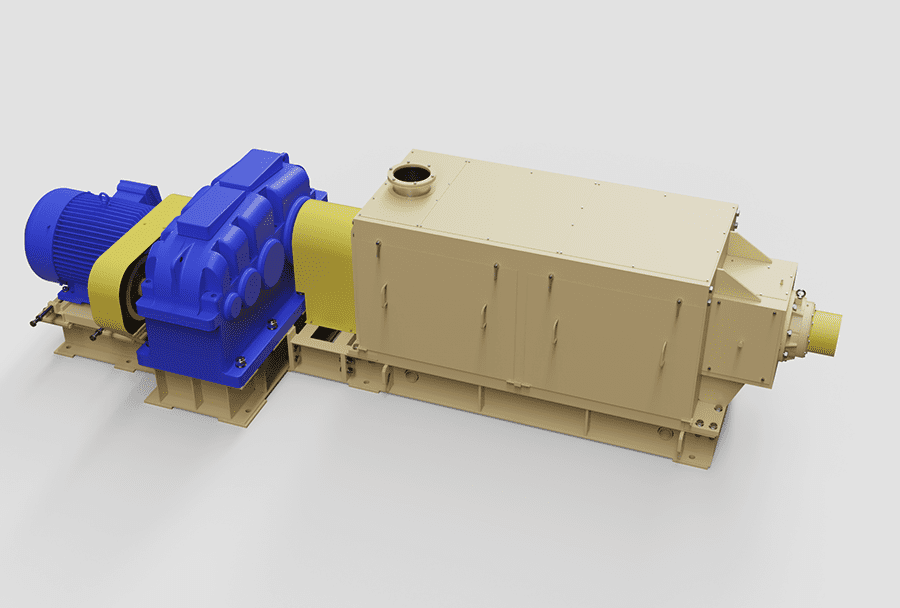

Equipment description

Cooker is a device in the form of a vertical column consisting of several trays. The number and diameter of the trays depends on the capacity of the device. The trays are united in sections, equipped with partitions (bottoms) and steam jackets. All jackets are heated with hot water steam supplied by the steam supply system.

All cookers manufactured by “TAN” company are equipped with:

- condensate removal systems that remove condensate and waste steam;

- special blade mixers that mix and move raw materials inside the tray;

- an electric drive that moves the mixers;

- regulating valves that maintain the normal level of crushed raw materials in trays;

- aspiration pipes and an air duct for removing gaseous products.

The temperature of the raw material (crushed oilseeds) before feeding into the oil press can be adjusted manually or with the help of an automatic adjustment system. Cooling of raw materials after the oil press can be carried out using a cake cooler.

Characteristics and operating conditions of the equipment

Wet-and-heat treatment of raw materials in cookers is an important stage of vegetable oil production, the purpose of which is to obtain at the output raw materials ideally prepared for further processing – oil pressing. The capacity of the cooker should be selected taking into account the production volume of the enterprise. For instance, the model Ж-2100-3 is capable of processing 45 tons of raw materials per day, and the model Ж-3200-10 – 400 tons.

|

Brand of the Cooker Technical parameter |

Ж-2100-3 |

Ж-2100-4 |

Ж-2100-5 |

Ж-2100-6 |

Ж-2100-7 |

Ж-3200-3 |

Ж-3200-4 |

Ж-3200-5 |

Ж-3200-6 |

Ж-3200-7 |

Ж-3200-8 |

Ж-3200-10 |

|

Diameter of trays, mm |

2100 |

3200 |

||||||||||

|

Capacity, tpd |

45 |

65 |

90 |

110 |

135 |

115 |

150 |

180 |

240 |

270 |

300 |

400 |

|

Heat exchange surface, m2 |

18 |

24 |

30 |

35 |

40 |

34 |

46 |

58 |

70 |

82 |

95 |

115 |

|

Working pressure, MPa |

0,6 |

1,0 |

||||||||||

|

Steam expanses, kg/hour, not more |

450 |

580 |

700 |

820 |

900 |

850 |

1100 |

1300 |

1600 |

2000 |

2500 |

2500 |

|

Installed power, kW |

18,5 |

22 |

30 |

30 |

37 |

34 |

46 |

58 |

70 |

82 |

95 |

115 |

|

Weight, tons, not more |

5,6 |

7,2 |

10,0 |

11,0 |

14,0 |

15,0 |

18,0 |

22,0 |

26,0 |

30,0 |

33,0 |

46,0 |

|

Shaft rotation frequency, rpm |

25-30 |

15-20 |

||||||||||

|

Temperature on the outlet, оС |

от 90 до 110 |

|||||||||||

“TAN” LLC designs, manufactures and installs equipment for edible oil production. In addition to cookers, you can buy a full range of equipment from us, including sludge catchers, separators, extractors, oil presses and other devices. They are available both individually and as part of complex lines. To design a turnkey production line or find out the price of its individual components, call the numbers in the header of the site or send us an inquiry by e-mail.