Oil Pressing lines

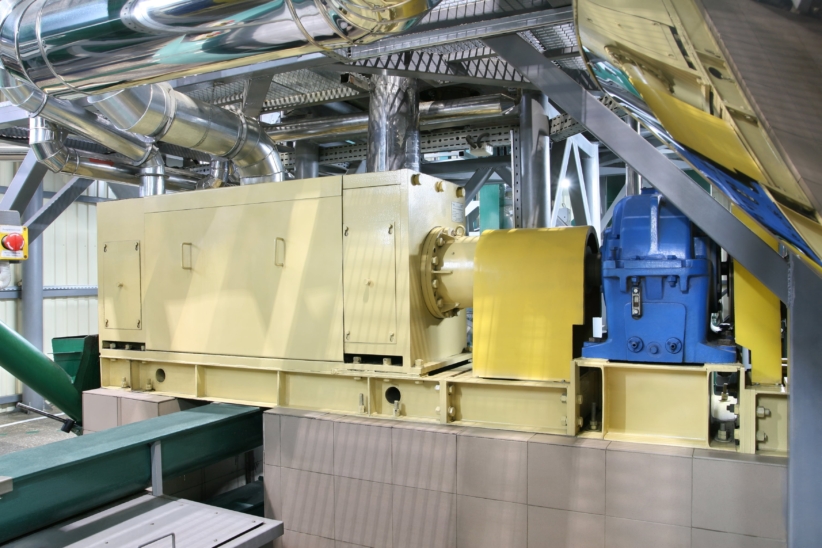

Description of technological line

Our company produces a full range of equipment for completing the oil pressing line according to customer requirements. You can buy the oil pressing lines of our production with the capacity beginning with 50 tons per day. The maximum capacity is limited only by customer requirements. The price depends on the configuration of the line and technological features of the equipment. The oil pressing line is easy to install and commission, requires less initial investment and working space than solvent extraction line, but performs all the functions required for the production of edible oil. The line allows processing of many types of oil crops, including sunflower seeds, rapeseed, cotton, corn, soybeans. The automated system ensures stable operation at the plants for the production of sunflower and other oils. For further processing of oil, we produce lines of primary purification and winterization of oil.Features of the oil pressing line

Oil pressing lines supplied by our company can be completed in three different variants. All three schemes are based on the classic method of hot mechanical pressing using wet-and-heat treatment of seeds (sunflower, rapeseed, soybean etc.) before pressing:

- Oil pressing line for further solvent extraction. This scheme involves the completion of the line with roller mills, cookers and oil presses (forpresses) of our production. The residual oil content of the cake after pressing according to this scheme is 18-22%. According to this scheme, after oil pressing section and before extraction section, we highly recommend installation of the expander, which will significantly improve the further extraction performance.

- Classic scheme of double pressing. According to the classic scheme, the pressing line is equipped with roller mills, cookers for wet-and-heat treatment of the material before preliminary pressing, forpresses, cookers for wet-and-heat treatment of the cake before final pressing, and oil presses for final pressing. The residual oil content of the cake after the final pressing is 8-10%.

- Single pressing. According to this scheme, the pressing line is equipped with roller mills, cookers for wet-and-heat treatment of the material and oil presses. The residual oil content of the cake in this case is 10-12%.

In addition to complex oil pressing lines, our company can supply individual units of equipment:

- Roller mills with a capacity of 100 and 300 tpd.

- Cookers with a capacity of 30 to 600 tpd and a diameter of 1200 to 4500 mm.

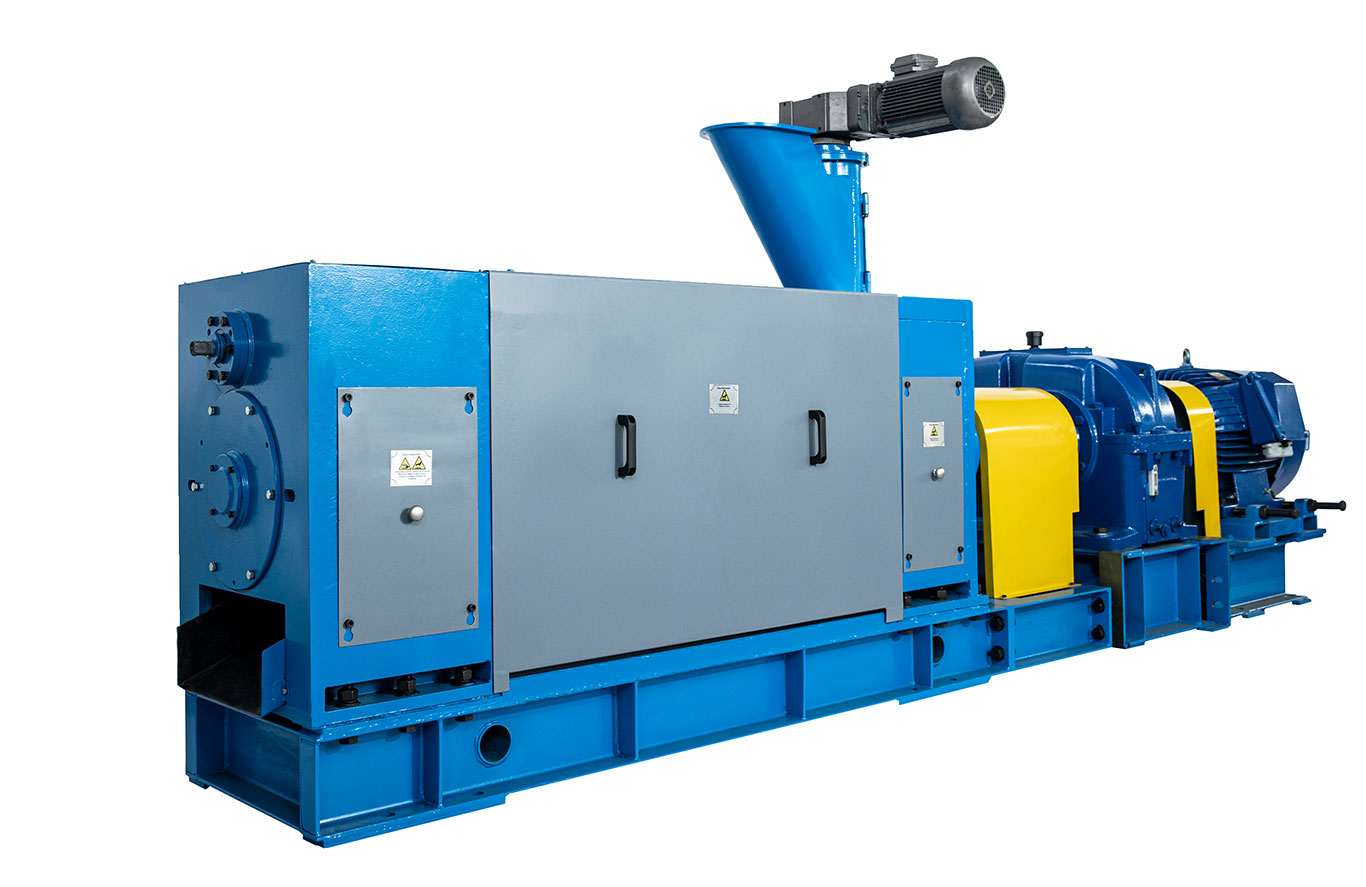

- Screw oil presses:

- forpresses with capacity from 70 to 300 tpd and residual oil content of 18-22%.

- presses for final pressing with capacity from 25 to 70 tpd and residual oil content of 8-10%.

The company “TAN” takes into account the requirements of customers towards the production of lines and separate equipment. Contact us to discuss the technological features of the equipment and clarify the prices. You can also buy oil deodorizing lines from us, which are suitable for plants producing sunflower and other oils. We supply equipment to all regions of Ukraine, as well as other countries.