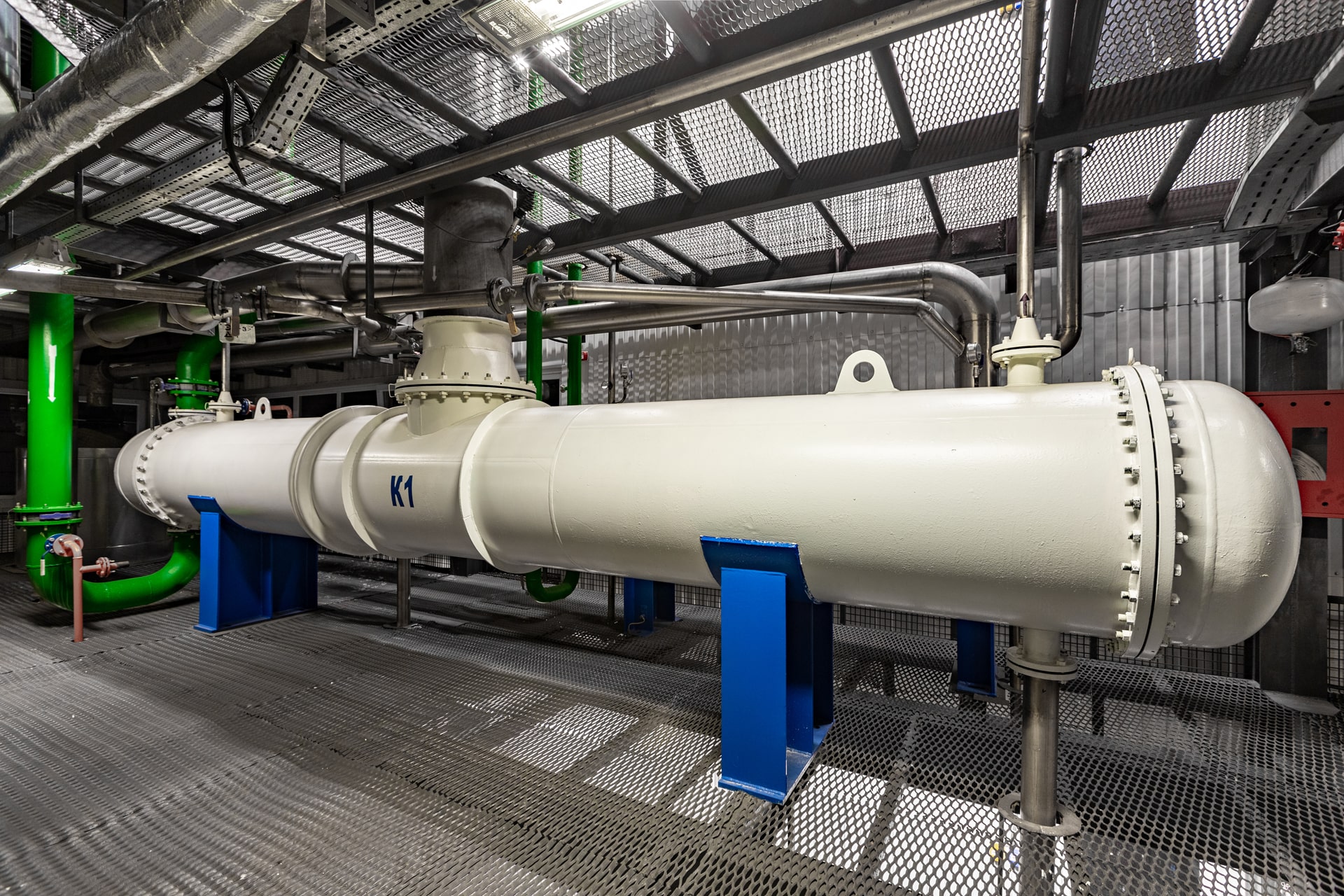

Heat exchanger for oil factory

Image gallery

A large number of technological equipment is used at the factories engaged in the production and processing of vegetable oils, among which a separate niche is occupied by heat exchanging devices. The catalog of “TAN” company includes a large assortment of heat exchanging devices of various types, the price and availability of which you can find out by contacting us at the phone numbers indicated in the header of the site or by sending us a request using the feedback form.

Heat exchanging device is a device designed to transfer heat from one heat carrier to another. A heat carrier with a higher temperature gives heat to the environment with a lower temperature by heating the heat exchange surface.

Heat exchanging devices differ depending on:

- type of heat exchanging surface: shell-and-tube (heat exchanging surface is represented by tubes), plate (heat exchanging surface is represented by plates), contact (heat exchanging surface is absent, and the heat carriers are in direct contact with each other);

- function of the device: heat exchangers (coolers, heaters), condensers, distillers, etc.;

- spatial orientation: horizontal, vertical;

- the type and availability of the heat carrier: the heat carrier is represented by liquid or gas, or there is no heat carrier and a heating element is used instead.

Company “TAN” is a manufacturer of the following types of heat exchanging devices:

– heat exchangers;

– condensers;

– distillers;

The heat exchanger of our production is a vertical cylindrical heat exchanging apparatus with a pipe coil inside (“shell-and-tube” or “pipe-in-pipe” type). The purpose of such heat exchangers is heating the product (heaters) or cooling the product (coolers) in oil processing cycles.

In particular, during the winterization process, in the process of winterization during the movement of oil in the coil, it is heated from 6°C to 15°C. This is done in order to improve the performance of further filtration and removal of waxy substances.

Heat exchangers manufactured by TAN can be equipped with both a coolant circulation system and an electric heating element.

During the manufacturing process of complex technological lines or oil refineries, we also use European-made plate heat exchangers, in which heat exchange takes place on flat or corrugated plates.

Condensers of our production are of shell-and-tube type as well. The main purpose of such devices is the condensation of moisture from the air-water mixture. By design, shell-and-tube condenser is a vertical or horizontal heat exchanging device equipped with tubular gratings. A cold coolant (water or vegetable oil) is supplied into the tubes, and a steam-air mixture is fed into the intertubular space of the condenser, where the steam condenses and is discharged through the fittings.

For example, in the extraction process, these devices are used to condense solvent vapors coming from the toaster, to reduce its losses and further reuse. In this case, the water supplied into tubular space acts as a cooling liquid.

Distillers are heat exchanging devices that are used to evaporate liquid. In particular, the distillers manufactured by “TAN” company are used at extraction plants in distillation lines to evaporate the solvent from miscella, as well as in fatty acids distillation lines to separate fatty acids from the tar.

The distiller for evaporation of the solvent from miscella is a shell-and-tube heat exchanging device, in the tubular space of which there is miscella (mixture of solvent and oil) under vacuum, and in the intertubular space – saturated steam under pressure. The miscella in the tubes boils and the solvent vapors are removed for condensation, while the miscella is sent for further processing to completely remove traces of the solvent.

To get more detailed information about the characteristics, prices, availability of heat exchanging devices and other equipment manufactured by “TAN” company, send us a request using the feedback form, or contact us at the phones indicated in the header of the site. Our managers will advise you on all issues, including how to purchase our equipment in Ukraine and abroad.