Phosphatides drying line

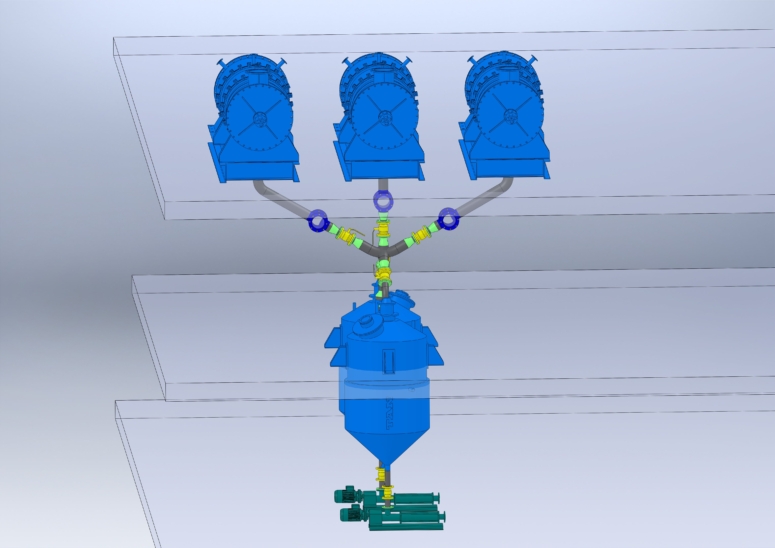

Description of the production line

Phosphatides drying lines are designed to obtain phosphatide concentrate from phosphatide emulsion with a high concentration of moisture obtained in the process of hydration of vegetable oils.

The drying of phosphatide emulsion takes place directly in rotafilm apparatuses, about which you can read more on the corresponding page of our website.

The principle of operation of the phosphatide drying line

From the output tanks, the gums in the form of a phosphatide emulsion is continuously fed to the rotafilm apparatus, in which it is distributed in a thin film over the inner surface of the housing. Under the influence of the steam fed into the jacket of the apparatus and the vacuum created by the steam ejector block, moisture is removed from the gums to obtain a phosphatide concentrate. The phosphatide concentrate is continuously poured into one of the tanks, after which, if necessary, the phosphatide concentrate is cooled with circulating water under vacuum and sent for storage or further processing.