Automation of equipment and complex lines

TAN offers turnkey solutions in form of an integrated automated control system for plants and lines for the production of vegetable oils from sunflower seeds and other crops. Automation can be implemented both at the stages of construction and reconstruction or in already operating workshops.

Automation of equipment and complex lines for edible oils production

Automation of the technological process is a set of methods and tools designed to create a system or systems that allow the management of the technological process itself without direct human intervention, or leaving the right to make the most critical decisions to the personnel.

Our systems can be implemented for automation of all production processes:

- control of transport mechanisms;

- weighing and dosing processes;

- oil pressing;

- extraction and distillation;

- refining.

Automated process control systems nowadays are an integral part of most modern enterprises producing edible oils. Such systems allow implementing a variety of tasks that arise as a result of the technological process execution.

How the process of automation of the oil-and-fat industry is performed

Automation of the equipment on the oil producing factories can be performed in two ways:

1st – design and installation of the system is performed directly during the construction of a new enterprise;

2nd – reconstruction of existing control systems with full or partial replacement.

TAN LLC develops systems designed for real-time operation and designed to display and control various technological processes. Our company can develop systems for both batch and continuous operation of vegetable oil processing and refining lines. We supply automation systems in Ukraine and abroad.

The automation system offered by our company usually is developed in compliance with the customer’s requirements and by default it includes:

- Control cabinet based on programmable logic controller (PLC). It collects and processes data from sensors, valves, motors and accordingly controls the operation of motors, controllers, etc.

- Control cabinet for electrical equipment for control and protection of motors, mixers, etc.

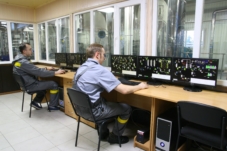

- SCADA System that allows controlling and recording all necessary process parameters.

The final configuration and price depends on the specifics of the production process and the equipment installed.

The main advantages of automation of equipment and complex lines

Development of the automation technologies involves a comprehensive improvement of production aimed at saving labor, material, fuel and energy resources.

Automation of production lines and individual units of equipment will provide the following benefits:

- significant reduction of risks of emergencies due to the exclusion of the human factor;

- the possibility to monitor all technological parameters of the process and the state of the equipment in real time from anywhere in the world;

- improving the reliable operation of the equipment;

- convenience and simplicity in operation of equipment and complex lines due to visualization of processes.

By controlling all processes, automation will significantly increase the safety of the production workshop and improve the working conditions of the staff.

Advantages of cooperation with TAN company

TAN LLC is a manufacturer of equipment and processing lines with many years of experience. We offer our customers a comprehensive approach: you can order separate equipment or a complete technological line for sunflower seed processing and oil production. You will also need an automation system to launch the enterprise. Our systems are equipped with modern leading equipment:

- VEGA;

- KROHNE;

- WIKA;

- Mitsubishi Electric;

- JUMO;

- ARI ARMATUREN;

- Bernecker;

- Rainer Industrie Elektronik GmbH.

We adapt to the needs of the customer, so it is possible to install components from other manufacturers. Prices are discussed individually. Our company also provides warranty and post-warranty service, and all equipment is covered by a 2-year warranty. We are open to cooperation with plants in Ukraine and abroad.

|

|

Our company can develop systems for both batch and continuous operation of lines for production and processing of vegetable oils.

The automation system offered by our company usually includes:

- Control cabinet based on programmable logic controller (PLC) (it collects and processes data from sensors, valves, motors and accordingly controls the operation of motors, controllers, etc.)

- Control cabinet for electrical equipment (control and protection of motors, mixers, etc.)

- SCADA System (system that allows controlling and recording all necessary process parameters).

Our systems are equipped with modern leading equipment: VEGA, KROHNE, WIKA, Mitsubishi Electric, JUMO, ARI ARMATUREN, Bernecker and Rainer Industrie Elektronik GmbH (and others – at Customer’s request).