Roller mills

Gallery of images

Roller mills are used in the oil pressing shops of oil production enterprises and are designed for continuous mechanical grinding of oilseed kernels (sunflower, rapeseed, soybean, etc.). The product obtained after roller mills is called “oilcake” and serves as a semi-finished product in the subsequent production of oil by pressing.

Roller mills are designed for continuous round-the-clock work with breaks only for maintenance, preventive, scheduled and unscheduled repairs.

All the mills of our production are completed with the adjustment mechanism of clearance between the rolls that allows to use them for crushing of kernels of various oil crops with the minimum expenses of forces and time for readjustment.

Also all roller mills are completed with metal catchers.

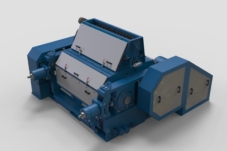

Our company produces two types of roller mills – four-roller (brand СВ-400/4) and two-roller (brand СВ-800/2).

The roller mill of the brand СВ-400/4 consists of four rolls made of bleached cast iron which are vertically located one above another. The rolls are rotated by means of two V-belt transmissions. The upper two rolls are corrugated that simplifies the capture of the material and its preliminary grinding. The two lower rolls are smooth that provides a uniform layer of material at the exit of the machine. Scraper knives are used to clean the surface of the rolls from the material that sticks to them.

In order to avoid contact of the rolls when the machine is idling, the design provides wedge mechanisms that allow establishing of guaranteed gaps between the rolls.

The material is fed to the machine by means of a feed roller.

Main technical parameters of the roller mill of the brand СВ-400/4

Technical parameterValue

Capacity, tpd:

for sunflower seeds 90-100

for rapeseed 60-70

Passage through a 1 mm sieve cell, %, not more60

Outer diameter of working rolls, mm 400-1,5

Number of working rolls, pcs. 4

Thickness of processed material parts, mm0-2,0

Installed electric power, kW 37 (2×18.5)

Overall dimensions, mm, not more

length 2500

width 1800

height 2500

Weight, kg, not more9800

The roller machine of the brand СВ-800/2 consists of two rolls made of bleached cast iron, installed in bearing supports on a common frame. The rolls rotate at different speeds and are driven by an electric drive. Both rolls of the roller machine of the brand СВ-800/2 are smooth and scraper knives are used to clean their surface from the sticky material. The material is fed by a feeder device into the gap between the rollers, which is regulated and maintained by a hydraulic system.

Main technical parameters of the roller mill of the brand СВ-800/2

Technical parameterValue

Capacity, tpd:

for sunflower seeds 250-300

for rapeseed 160-180

Passage through 1 mm of the sieve cell, %, not more 60

Outer diameter of working rolls, mm 800-0,2

Number of working rolls, pcs. 2

Thickness of processed material parts, mm 0,25-0,4

Installed electric power, kW 114.1

Overall dimensions, mm, no more

length 3050

width 3700

height 1850

Weight, kg, not more 22,000