Impact of different pressing methods on the quality and nutritional properties of sunflower oil

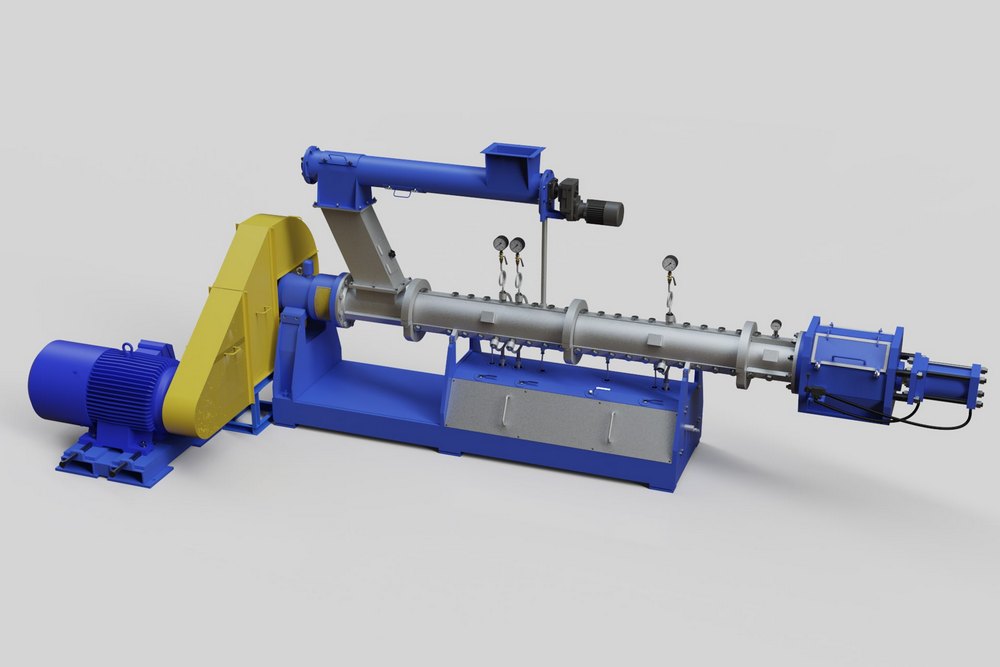

The demand for vegetable oils is constantly growing. To make it a true source of microelements, beneficial vitamins and amino acids, the production process must be carried out properly: prepare the raw materials for processing; process it; process the final product. Oil can be produced by extraction using solvents or by cold and hot pressing using various equipment assembled into a pressing line. TAN offers high-quality equipment for oil and fat plants at attractive prices. Our experts will help you choose the best equipment option. Basics of sunflower oil production If we are talking about the pressing method to produce oil, the production technology involves the following steps drying of sunflower seeds; cleaning the seeds from debris and husks; hulling (destruction of seed shells by mechanical action); separation of the husk into kernels and husks; grinding kernels on rolling machines to produce oilcake (pulp). The latter is a semi-finished product […]