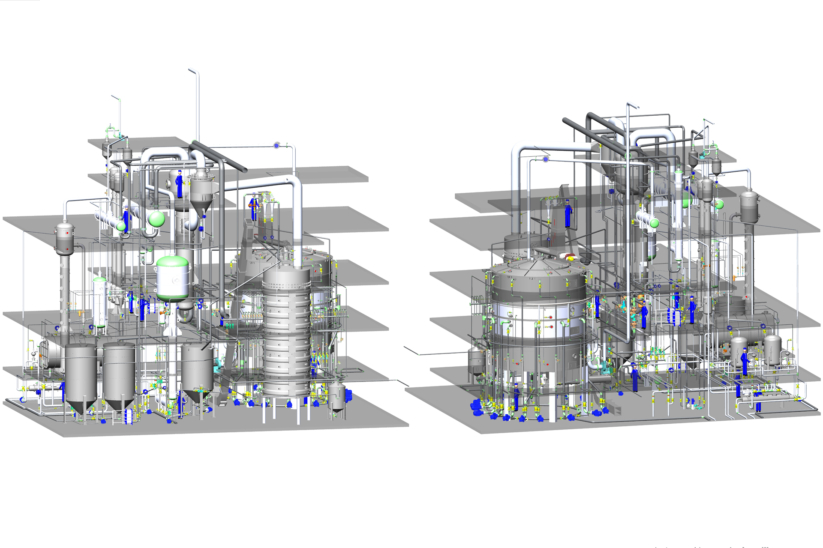

Vegetable oil extraction line

Description of the production line

Oil extraction is carried out on extraction lines, and consists in extracting oil from cake using organic solvents. The residual oil content of the meal (material after extraction) is not more than 1%.

The capacity of the extraction lines supplied by our company varies from 250 t/day to 1000 t/day for sunflower seeds.

The principle of operation of the extraction line

Oil extraction line is controlled by the main computer using the SCADA interface. All equipment of the extraction line is managed comprehensively – the alarm system is automatically turned on/off and regulated, the operation of all pumps, devices, automatic valves and electric motors is monitored.

From the oil press or expander, the cake is fed by a conveyor in the form of porous granules to the extractor. The oil is extracted using a solvent preheated to 60 degrees.

Once in the extractor, the cake is washed with miscella (a mixture of solvent, oil and solid material particles), which is supplied by circulation pumps. In the process of transportation along the extractor body, the material is washed with misceall, the concentration of which gradually decreases. The final stage of washing takes place with fresh solvent.

The meal coming out of the extractor is fed into the toaster, designed to remove the remains of the solvent from the meal. Its trays consist of a jacket and bottoms, which are constantly heated by indirect steam. In addition, direct steam is supplied for constant removal of the solvent from the meal.

The concentrated mixture is fed to the distillation sector. In the 1st stage distiller, it is heated by solvent vapors from the toaster. During this process, part of the solvent evaporates and is removed from the distiller.

At the next stage, the mixture is fed to the 2nd stage of distillation, where it is heated by indirect steam. After that, it passes into the 3rd stage distiller for the final distillation of the solvent by means of contact of direct steam with a concentrated miscella.

After the 3rd stage of distillation, the oil is fed into a dryer, in which moisture is extracted by deep vacuum. After cooling and recovery heat exchanger, the oil is fed into storage tanks.

Distillation and drying of vegetable oil takes place under a vacuum created by steam jet ejectors.