Vertical pressure leaf filter for vegetable oil

Equipment Description

Filters of the brand ВНП (vertical pressure leaf) are designed for purification of technical and edible oils on the different stages of processing:

– primary purification of vegetable oils;

– in lines of winterization of vegetable oils;

– in lines of bleaching of vegetable oils;

– separation of catalyst in the lines generating hydrogenated fat.

Vertical filters can be also used for filtration of other substances (non-aggressive to carbon steel).

Operating principle

The vertical filter for purification of vegetable oil represents a vertical vessel with a movable torospheric cover. It is installed on a movable rod and makes the vessel airtight after tightening the hinged bolts. The cover of the vertical filter is lifted by a special jack and removed to the side by a rotary bracket.

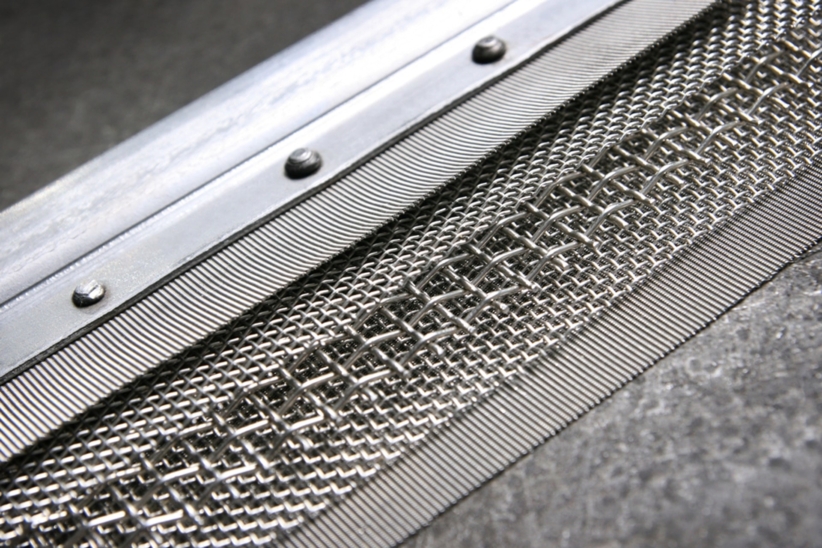

The function of the filter elements of the filter is performed by vertical steel plates installed in its body. Filter plates consist of 5 layers of steel mesh: 1 layer of frame mesh, 2 layers of backing mesh and 2 layers of filter mesh. Depending on the process on which the filter is installed, the filter mesh itself differs in weaving and material of manufacture.

Pressure filters have a number of advantages over outdated frame (belting-cloth) filters:

– filtering cloth is not used, instead of it high quality durable stainless steel mesh is used;

– automatic sediment discharge (vibrodischarge);

– simple service;

– no contact of oil with air means no icnrease in acid and peroxide index;

– minimal oil losses.

Technical parameters of vertical filters of the brand ВНП

Filter model Technical parameter | ВНП-6 | ВНП-10 | ВНП-15 | ВНП-20 | ВНП-24 | ВНП-30 | ВНП-40 | ВНП-45 | ВНП-60 | ВНП-75 |

Filtration area, m2 | 5,7 | 8,3 | 12,8 | 15,5 | 19 | 26,4 | 37,2 | 45,13 | 59,4 | 72,2 |

Number of filter plates, pcs | 7 | 8 | 10 | 11 | 12 | 12 | 14 | 15 | 17 | 19 |

Capacity on the process of primary purification of sunflower oil (hot-pressed, with temperature 75-90 oC), tpd | 10,4 | 15,2 | 23,6 | 28,0 | 35,0 | 48,0 | 66,0 | 80,5 | 107,0 | 135,7 |

Working volume, m3 | 0,52 | 1,0 | 1,35 | 1,6 | 1,95 | 2,4 | 3,5 | 3,7 | 4,8 | 7,35 |

Compressed air consumption (at 0.07 MPa) for sediment drying, nm3/min | 1,2 | 2,0 | 2,6 | 3,2 | 3,8 | 6 | 9 | 9 | 12 | 15 |

Maximum cake volume, m3 | 0,12 | 0,2 | 0,26 | 0,32 | 0,38 | 0,65 | 0,9 | 0,9 | 1,2 | 1,5 |

Cake thickness, mm | 20 | |||||||||

Working pressure, MPa, not more | 0,6 | |||||||||

Test pressure, MPa | 0,75 | |||||||||

Working temperature, оС, not more | 95 | |||||||||

Weight of empty apparatus, kg, not more | 560 | 710 | 900 | 1000 | 1100 | 1300 | 2000 | 2150 | 2960 | 3400 |

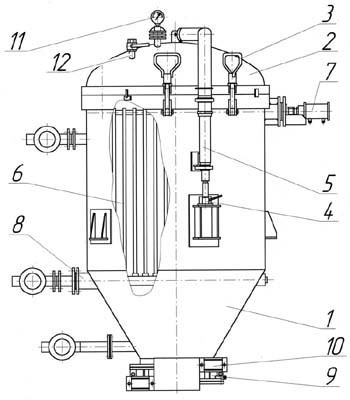

Схема фильтра ВНП:

- корпус;

- крышка;

- откидной болт;

- домкрат;

- кронштейн поворотный;

- фильтровальные пластины;

- вибратор пневматический;

- сборный коллектор;

- донный клапан (затвор);

- пневмоцилиндр;

- манометр;

- шаровой кран