Oilcake cooler

Gallery of images

Description of the equipment

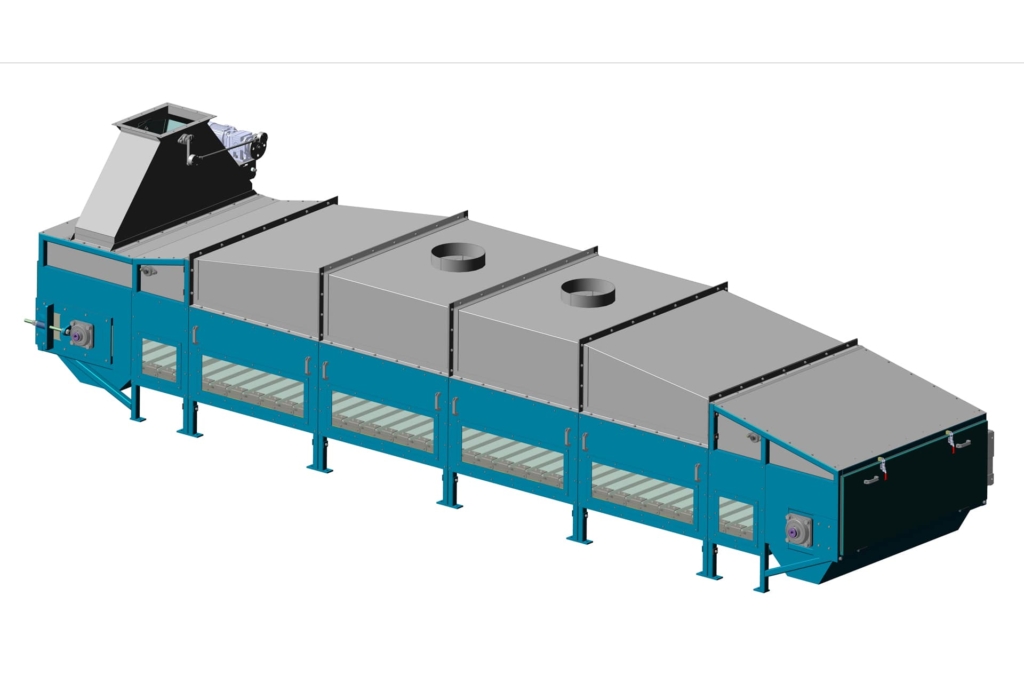

Oilcake coolers are designed to reduce the temperature and humidity of cake granules after mechanical pressing of oil that guarantees their stable storage.

Principle of action

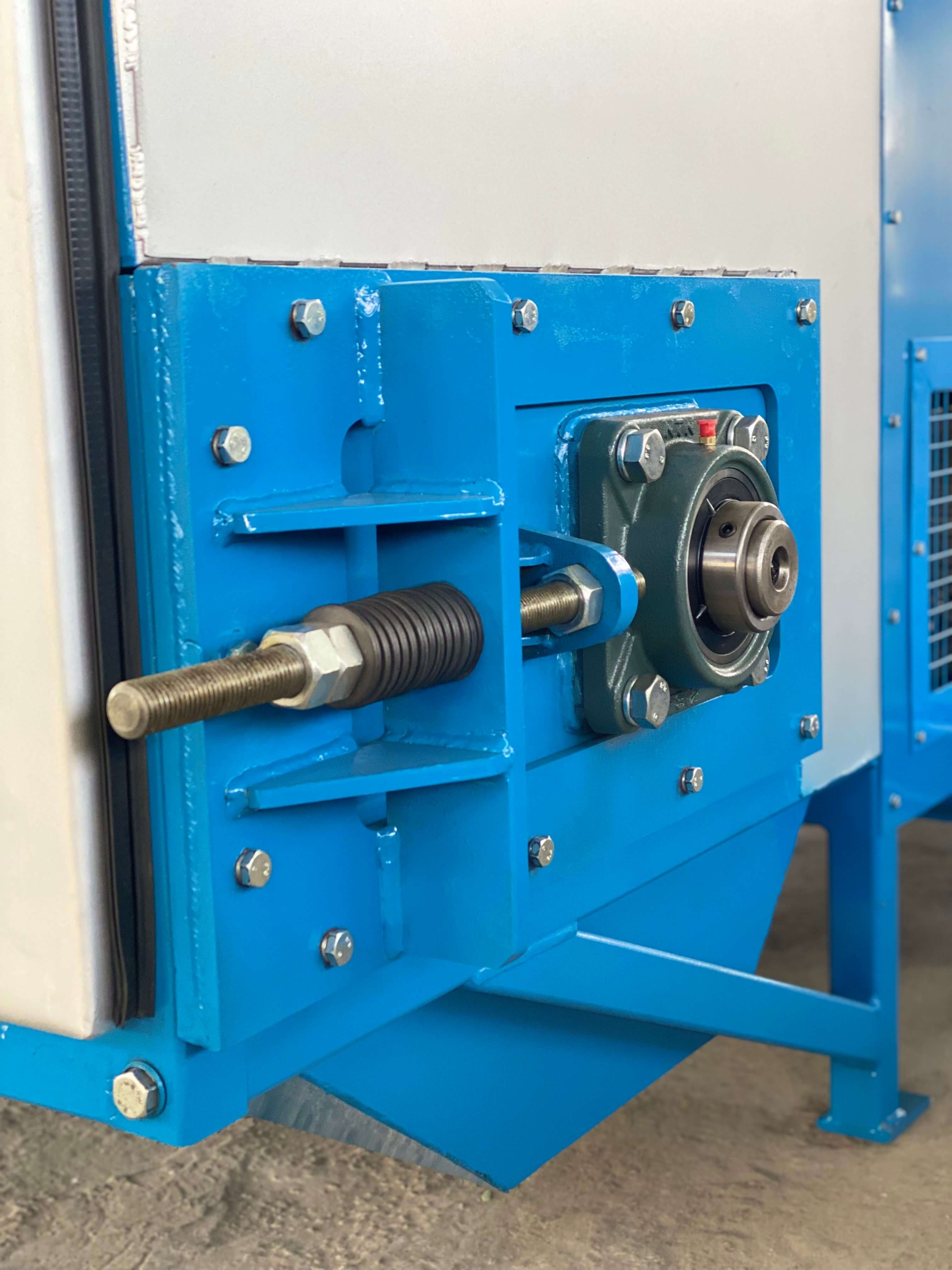

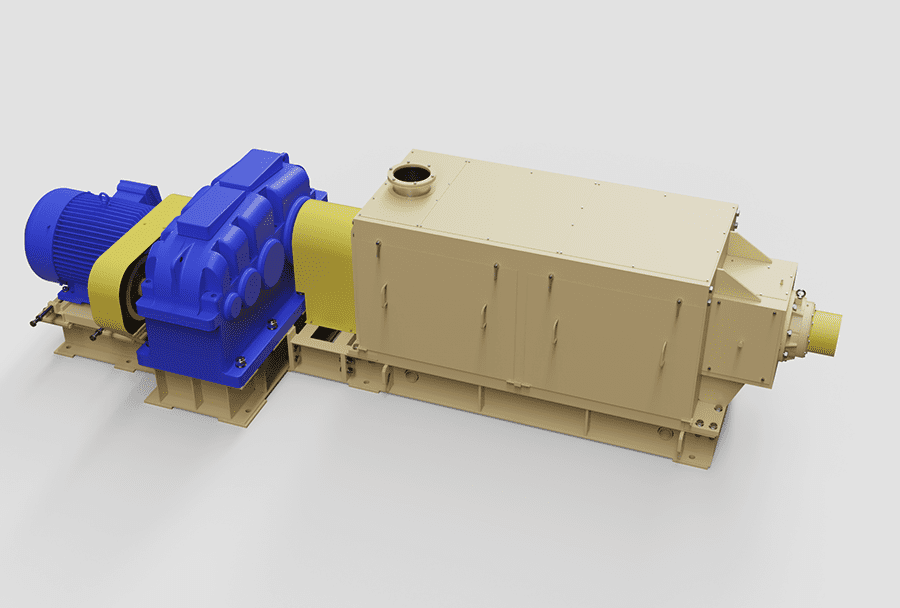

Cooling is performed by means of blowing through the oilcake granules with a huge amount of cold air, which enters the perforated trays through a special spreader and is evenly distributed across the width of the tray. The fine fraction (up to 3 mm) is taken through a sieve of trays. Even loading of the transport element is provided by means of adjusting the speed of the conveyor.

Air for cooling of the product is collected under the perforated trays of the conveyor, passes through the product and through the air duct enters the cyclone, from which it is removed by an exhaust fan.

In oilcake coolers it is possible to regulate the temperature of the product at the outlet, by changing the amount of air passing through the material, using a damper.

Oilcake coolers can be produced in different types, form factors and configurations. Oilcake coolers of our production are horizontal conveyor-type.

The main technical parameters of the oilcake cooler of the brand ОГ-500

|

Technical parameters |

Oilcake cooler of the brand ОГ-500 |

|

Capacity, tpd, based on sunflower oilcake, at height of the layer not more 100 mm |

10 |

|

Power of the main electric motor, kW |

0,75 |

|

Power of the feeder drive, kW |

0,55 |

|

Temperature of the product before cooling, оС, not more |

90 |

|

Temperature of the product after cooling, оС, not more |

15 оС above the room temperature |

|

The length of the conveyor route, m |

6,8 |

|

Conveyor speed, m/min |

2 |

|

The weight of the filled device, kg |

5000 |

|

Dimensions, LхWхH, mm |

7850х2210х2110 |