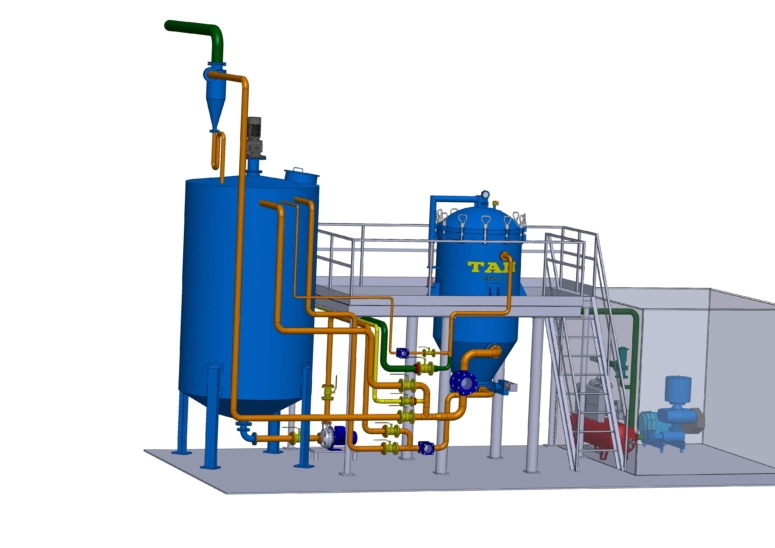

Line of primary purification of vegetable oil

Description of the production line

Oil purification is performed on primary purification lines. The purpose of such technological lines is to remove non-compressible mechanical impurities from pressed oil.

The lines of primary purification of vegetable oil of our production, depending on the client’s requirements, can be of continuous or batch action.

Our company produces primary purification lines with the capacity beginning with 10 tpd of sunflower oil and more.

The principle of operation of the primary purification line of vegetable oil

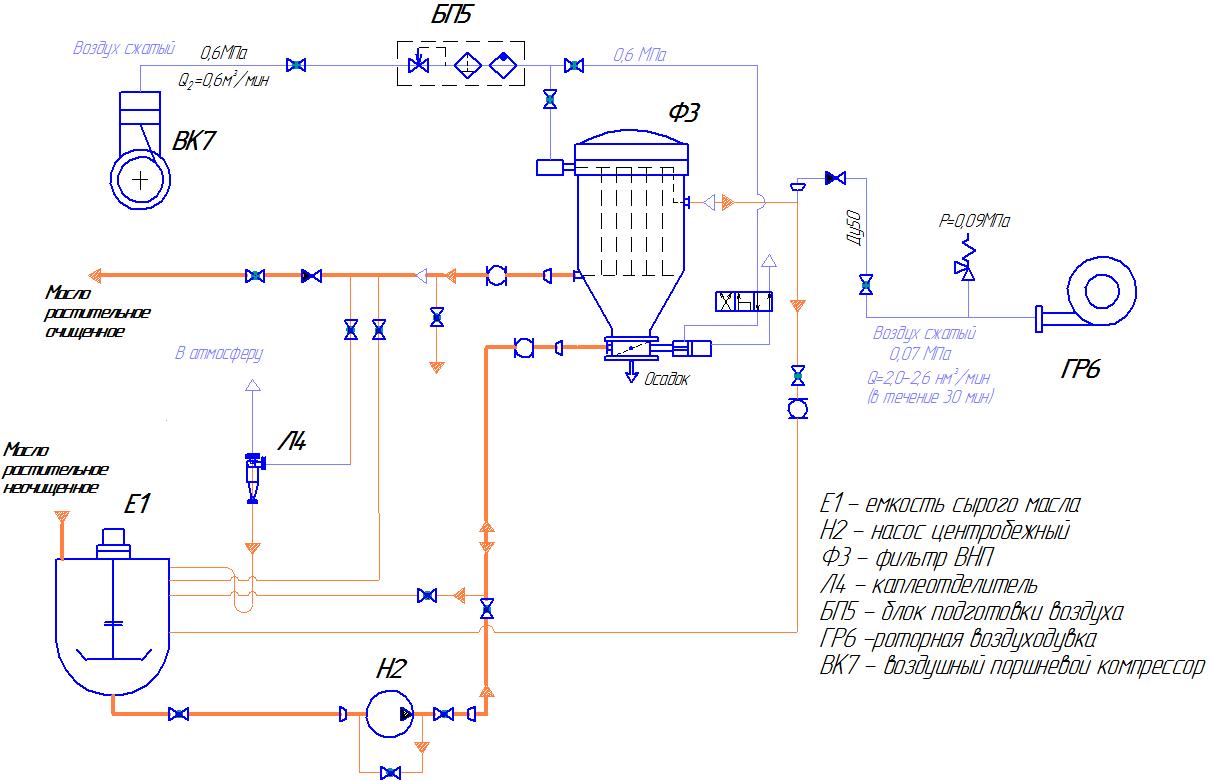

Step 1. Raw pressed oil is fed into the tank E1. A mixing device is installed in the tank to evenly wash the filter layer and avoid clogging of the output pipeline of the tank E1.

Before starting the filtration process, it is necessary to prepare the filter.

Step 2. Using the pump N2, oil is supplied to the filter F3 from the tank E1. The degree of filling of the filter is monitored using a special inspection sight glass. When the filter is completely filled, the shut-off device is switched and the operation mode of the device is switched to inwashing of the filter layer. Inwashing is performed by means of the circulation of vegetable oil in the following circle – tank E1 – pump N2 – filter F3 – tank E1. The appearance of clean oil in the output inspection sight glass indicates that inwashing process is complete. In this case, the shut-off valve is switched to the filtration mode (filtration process into the tank for filtered oil).

When the maximum allowable pressure level is reached during the filtration process or the performance falls down, the filter is switched to the drain mode. The remaining unfiltered oil is poured into the tank E1.

Step 3. After draining the filter, its air drying is carried out. Warm air created by rotary compressor is fed into the filter. Air leaves the filter passing through the filter layer. Remaining oil from the layer together with air enter the drop separator L4, where the separation of oil (returned to the tank E1) and air takes place. Thus, the oil is removed, and the filtered sediment becomes loose.

Step 4. With the help of pneumatic vibrator, filter sediment is shaken off the filter plates and walls of the filter. You just need to turn on the pneumatic vibrator by opening the bottom valve. Thus, filter F3 becomes ready for usage again.