Oil Shop Design Basics: Equipment Selection and Process Optimization

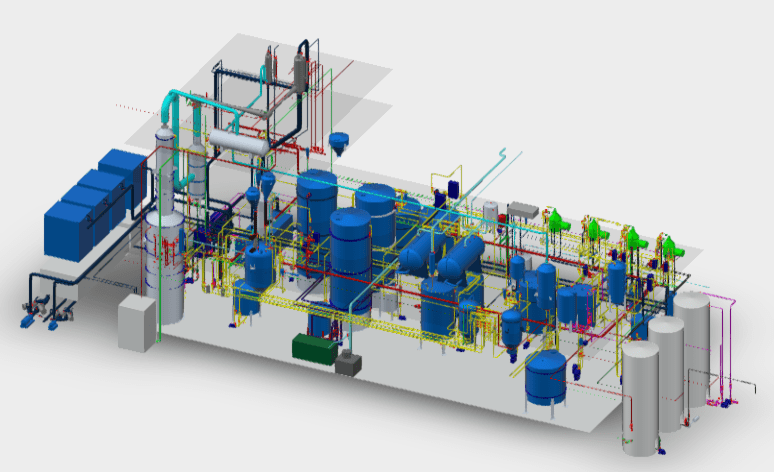

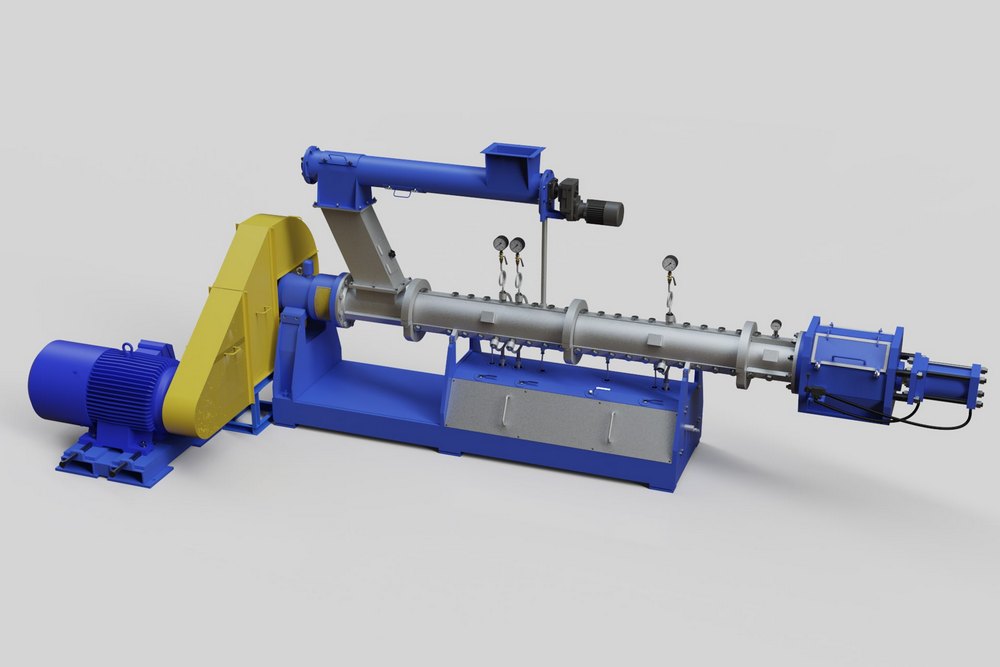

Project oil workshop is a complex process that requires knowledge in engineering, automation, energy efficiency and compliance with regulatory requirements. In this article, we will look at the key technical aspects of creating butlocechus, starting with the choice equipment and ending with the implementation of modern standards. Selection of appropriate equipment The basis of any production is equipment for technological lines, which must meet the requirements of performance, quality of raw materials processing and cost-effectiveness. The main types of oil storage equipment cover: Important nuance is also the choice of refining lines for cleaning oil and providing its high quality, which reduces the cost of materials and improve the efficiency of raw material processing. Space Planning and Equipment Localization Production of the space of butlocceum should ensure the most efficient use of the area and convenience for staff. Properly delayed butloczech minimizes logistics and time. Basic principles: In addition, do […]