Impact of different pressing methods on the quality and nutritional properties of sunflower oil

- 17.10.2023

- 9748

- Соняшникова олія

The demand for vegetable oils is constantly growing. To make it a true source of microelements, beneficial vitamins and amino acids, the production process must be carried out properly:

- prepare the raw materials for processing;

- process it;

- process the final product.

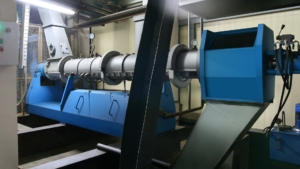

Oil can be produced by extraction using solvents or by cold and hot pressing using various equipment assembled into a pressing line.

TAN offers high-quality equipment for oil and fat plants at attractive prices. Our experts will help you choose the best equipment option.

Basics of sunflower oil production

If we are talking about the pressing method to produce oil, the production technology involves the following steps

- drying of sunflower seeds;

- cleaning the seeds from debris and husks;

- hulling (destruction of seed shells by mechanical action);

- separation of the husk into kernels and husks;

- grinding kernels on rolling machines to produce oilcake (pulp).

The latter is a semi-finished product ready for oil extraction using one of the above mentioned methods.

The oil pressing process and its importance

Depending on the method of oil extraction, the final product may vary: in case of pressing, both refined and unrefined oil can be used, and in case of extraction, only refined oil can be used. The healthiest is considered to be exactly unrefined sunflower oil, i.e. crude and unprocessed oil. It is produced by cold or hot pressing followed by filtration.

Hot pressing requires preheating of the raw material. The oil obtained using this method can be considered a finished product after filtering or undergo additional purification in the form of freezing or further refining.

When producing sunflower oil using the cold pressing method, the only additional processing is filtration using a vertical or horizontal pressure plate oil filter. Unlike the refined product, the unrefined product almost completely retains all the nutrients contained in the raw material:

- vitamins of groups A, B, D, E

- microelements required by the human body;

- saturated and unsaturated fatty acids.

In particular, this applies to polyunsaturated linoleic acid, which increases the body’s protective function. It helps cells survive in difficult conditions. However, unrefined oil should not be used for cooking.

Traditional cold pressing

This method of oil production is traditional, as it was used by our ancestors. The essence of cold pressing is that the temperature of the raw material should not exceed 40°C. It’s just that the wooden mortar used by our ancestors was later replaced by powerful mechanical presses.

Hot pressing

This method involves both mechanical and thermal treatment of raw materials. The latter means that before being placed into the press, the crushed kernels are roasted at a temperature of about 105-120 degrees. Although heating the raw materials simplifies the pressing process and increases the yield of the finished product, there is a risk of reducing the amount of nutrients in it.

Oil pressing with the further solvent extraction

In order to extract the maximum amount of oil from the oil cake remaining after the preliminary pressing, it is fed to extractors. There, it is mixed with gasoline of grades A, B, naphtha or hexane as solvents. This is how the miscella is formed – a mixture of solvent and oil. After that, the miscella is allowed to settle and is distilled, i.e. the oil is separated from the solvent. After several stages of distillation, the oil must be refined to completely remove the solvent.

Impact of oil pressing methods on oil properties

The sunflower oil obtained by hot pressing is characterized by its viscosity and dark color, intense aroma and taste. However, it loses many of the nutrients contained in the raw material. The oil obtained through the cold-pressing process is different:

- delicate aroma and taste, which reminds the taste of raw seeds;

- the presence of all the nutrients that are present in the plant.

It is less viscous and lighter than the product obtained by hot pressing. This oil is perfect for cold dishes. But it has a short shelf life.

Advantages and disadvantages of different oil pressing methods

Each type of pressing has its own pros and cons, its own specific features. The cold pressing method is characterized by:

- simplicity of the technical equipment used;

- small area required to accommodate the pressing line;

- lower energy consumption.

Hot pressing is characterized by the following features:

- higher oil yield;

- use of more energy-intensive technologies.

All elements necessary for the organization of a cold and hot pressing line are presented in a wide range at TAN LLC. You can place an order for any equipment by calling the phone numbers listed at the bottom of the site. It is also possible to order a call back. TAN specialists are ready to provide professional advice on the equipment that is optimal for your plant for the production of sunflower oil by any method.