Vegetable oil extractor: what is this and why is it used

Extraction is a popular way to extract vegetable oil. This method allows increasing the yield of the product. Extractors are a universal type of equipment used in production process. The extraction method of oil production can be used both in its pure form and in combination with mechanical pressing, which will allow you to get even more product.

Vegetable oil extractors

Extraction is the process of transferring oil from an oil-containing material to a solvent by means of molecular and convective diffusion. Continuous extraction is the main method for the degreasing of oilseeds. During the extraction process, the solvent can move either towards the raw material or in the same direction as it. In the first case, the process is called countercurrent, and in the second – forward flow.

Extractor operation principle

The entire extraction process includes 4 main steps:

- Extraction of oil by solvent from seeds or other raw materials. During this process, 2 products are formed: miscilla (solvent-oil substance) and meal with residual solvent content.

- Separation of the oil from the meal.

- Removal of solvent from the meal.

- Removal of solvent from miscella (separation from the oil).

Continuous methods are used to extract oil from raw materials. The batch method is not used due to its imperfection.

Types of extractors

Extractors have different designs, which also affect the principle of operation. They can be:

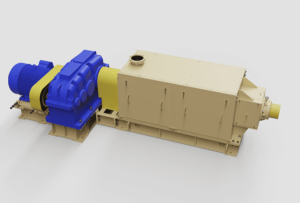

- Belt. The extractor operates based on the technology of step irrigation. All the working bodies of the extractor are enclosed in a box-shaped body made of sheet steel and channel bars. A horizontal mesh belt conveyor is located inside the housing.

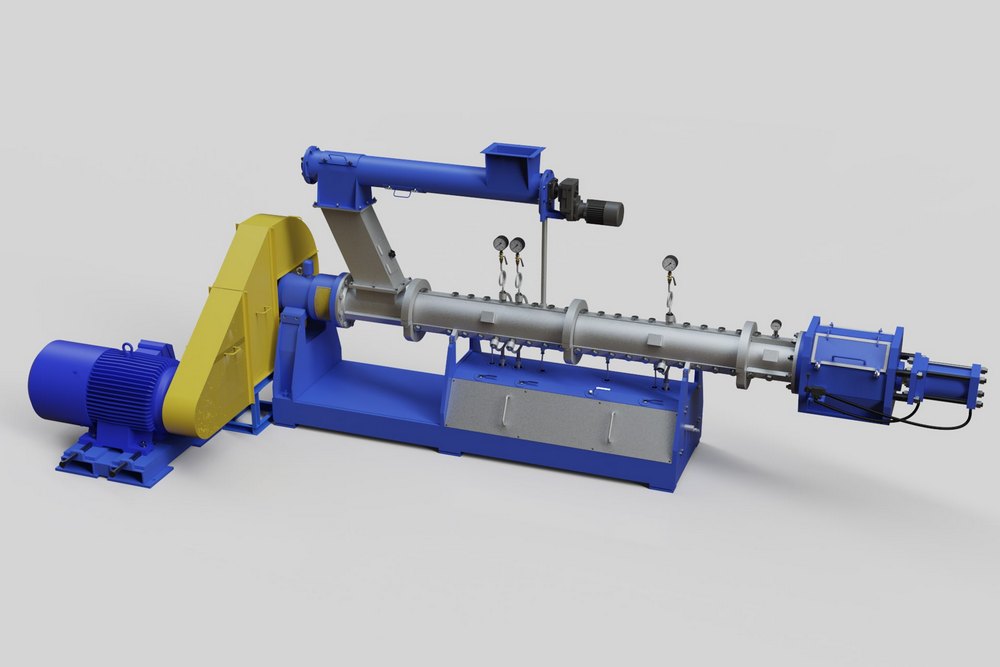

- Screw. The material enters the feeding column. At the top of the column, agitators distribute it evenly in the extractor column. The oil material moves downward while the solvent is simultaneously supplied towards it.

- Rotary (or carousel). The cylindrical apparatus consists of 1 or 2 tiers and an internal rotor. The material flows from the expander to the extractor’s feed bunker via a screw conveyor. The solvent is fed by a countercurrent to the direction of rotation of the extractor.

Extractors of TAN LLC production are of a carousel design and operate on the technology of stepwise irrigation.

Technologies used in extractors

There are two main extraction technologies for oil extraction: immersion and consecutive degreasing.

In extractors using immersion method, the raw material is poured into a clean solvent, resulting in a solution – miscella which is then drained off. The degreased cake is again filled with clean solvent and this is repeated until all the oil is completely extracted. The first portions of the miscella have a higher concentration, and gradually the concentration decreases.

In extractors that use the step-irrigation method, the solvent is continuously applied to the maximally degreased material, and the concentrated miscella is applied to the loaded raw material. In industrial oil production, the step irrigation method is more frequently used.

Benefits of using vegetable oil extractors

There are several advantages of vegetable oil production by extraction method:

- The extraction method provides more efficient extraction of oil from vegetable raw materials compared to other production methods. Thus, extraction is a more cost-effective technology.

- The extraction method is flexible, allowing the use of different technologies and processing options depending on the type of plant material and the desired end product. This allows producers to choose the optimal conditions and parameters to achieve the desired oil properties and quality.

- The extraction method can be used to produce oil from various raw materials. These include sunflower, soybean, rapeseed and other oils. Extraction allows consumers to have access to a wide range of oils with different flavors and properties.

Overall, the extraction method ensures high quality, efficiency, safety, flexibility, and product diversity, making it attractive to manufacturers.

Technological improvements and innovations in the field of extractors

The main innovations in oil extraction are related to the use of safe solvents. The extraction is carried out with ethyl alcohol, isopropyl alcohol, acetone, liquefied gases (propane-butane and others). Studies are being conducted on fat extraction from vegetable raw materials by the impulse method and with the use of ultrasound.

The importance of extractors in the production of vegetable oils

Extractors play an important role in the oil production. They are used to extract fat from plant material such as seeds, nuts, fruits or other plant materials. Extractors create the conditions under which the cell walls of plant material are destroyed and fat is released. The equipment provides high efficiency and can handle large volumes of raw materials.