How vegetable oil is refined

Content[ hide ]

- The main stages of the vegetable oil refining process

- Water degumming and neutralization

- Bleaching

- Winterization

- Deodorizing

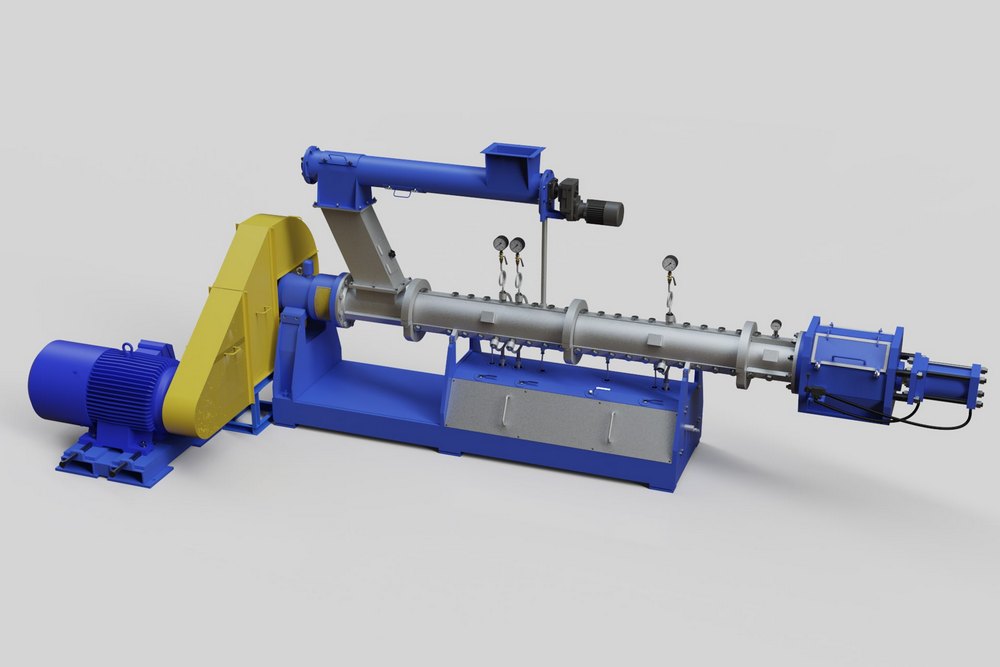

- Equipment for refining vegetable oil

- Benefits and importance of vegetable oil refining

- Improving oil quality and stability

- Ensuring a long shelf life

- Compliance with food safety standards